Since the reaction is incomplete in the primary reformer, a secondary reformer is used for converting the remaining hydrocarbons.Despite all preventive measures, a sizeable portion of pollutants can only be removed by the end-of-pipe methods, i.e. In the steam reformation process, desulphurized naphtha or natural gas is subjected to catalytic reforming in a primary reformer in the presence of steam to form carbon monoxide and hydrogen. A pre-treatment is necessary in order to protect raw water lifting systems and pipelines against blockages as well as other treatment equipment against abrasion and, more generally, to remove anything that might interfere with subsequent treatment.Richa Environmental Services Pvt Ltd Best quality Sewage Treatment Plant Manufacturer, Effluent treatment plant manufacturer from Delhi NCR India Manufacturer, Supplier, Design, Exporter.The raw gas is scrubbed with water for removal of the carbon formed during gasification and after desulphurization is sent to the shift conversion unit. Urban wastewater sewers carry a wide range of matter that is often bulky, especially in the case of combined systems.

Urea synthesis can be divided into three main sections, namely, synthesis, decomposition/recovery and finishing sections.In the synthesis sections ammonia and carbon dioxide are compressed in an autoclave at elevated temperature and pressure to form a solution of urea, ammonium carbonate and water. Urea is produced from ammonia and carbon dioxide obtained from ammonia plant normally located at the site of the urea plant. The raw gas produced is cleaned up before it goes for shift reaction for purification.The first step in the purification of raw synthesis gas is the shift conversion of carbon monoxide to carbon dioxide which is accomplished by reacting carbon monoxide with steam over activated iron oxide catalyst carbon dioxide thus produced with hydrogen is removed by absorption process by use of scrubbing solutions.Urea is the main nitrogenous fertilizer in India. Coal gasification process involves pulverized coal gasification in the presence of oxygen and steam. One of the most successful areas of interventions implemented or facilitated by UNIDO was designing and managing the construction of cost effective Common Effluent Treatment Plants (CETP).The Effluent Treatment Project (ETP) collects and treats wastewater that may be contaminated with small quantities of radionuclides and process chemicals.Air is injected into the secondary reformer to burn the unreacted hydrocarbons and supply the nitrogen requirement of the raw gas.

The ammonium sulphate crystals are separated by filtration and dried.Ammonium Nitrate and Calcium Ammonium Nitrate Production – Ammonia reacts with nitric acid in a neutralizer producing ammonium nitrate. The chalk is separated by filtration and the liquor is evaporated and crystallized. The ground gypsum is reacted with ammonium carbonate producing ammonium sulphate and chalk. This ammonia is converted into byproduct ammonium sulphate by reacting it with sulphuric acid.Ammonium sulphate is produced by neutralizing synthetic ammonia with sulphuric acid and the ammonium sulphate crystals formed are separated from the mother liquor by filtration or centrifuging.Ammonium sulphate is also manufactured from natural of byproduct gypsum.

Nitric Acid and Sulphuric Acid Production:In the industries where ammonium nitrate and ammonium sulphate are produced, nitric acid and sulphuric acid production plants are also installed. The hot granules are dried, screened, cooled and coated with soapstone dust in a coating drum stored.F. In the case of calcium ammonium nitrate (CAN), the concentrated liquor is pumped and sprayed into the granulator which is also fed with a measured quantity of limestone powder and recycle fines. In the neutralizer, concentrated ammonium nitrate solution is produced which is further concentrated in vacuum concentrators.In ammonium nitrate production, the concentration is carried out up to molten nitrate which is then sprayed from a prilling tower against an upward stream of air to produce prilled ammonium nitrate.

Both silicon fluorine and P 2O 5 remains along with the byproduct gypsum which poses disposal problems.After the reaction in the digester, the mixture of phosphoric acid and gypsum is pumped to filter where gypsum is separated from phosphoric acid. Some of the fluorine contained in the rock phosphate is evolved from the attack vessels as silicon tetrafluoride and hydrofluoric acid. The rock phosphate is converted into gypsum and phosphoric acid vessels.

The resultant slurry is then distributed on to dry recycled product. Different grades of ammonium phosphate vary only in the nitrogen and phosphate contents.Therefore, by controlling the degree of ammoniation during the neutralization of phosphoric acid, different grades of ammonium phosphate can be obtained Ammonia is reacted with phosphoric acid in vertical cylindrical vessels with or without agitation. It is dried in rotary driers and sized in vibrating screens before storage.Two primary raw materials for the production of ammonium phosphated are ammonia and phosphoric acid.

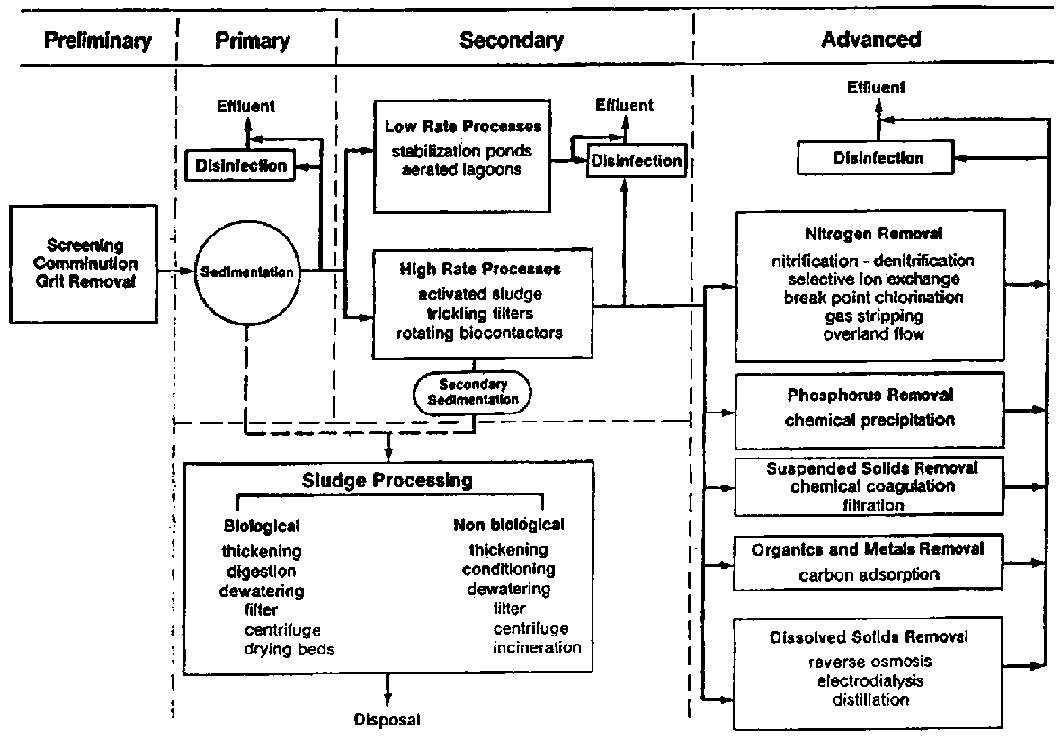

Effluent Treatment Methods Series Of Reaction

Sources, Volume and Characteristics of Effluents :1. This then converted into a dry product. Nitric acid and rock phosphate are mixed in a series of reaction vessels with agitation.In the first few vessels, the reaction products – calcium nitrate and phosphoric or sulphuric acid is added together with ammonia to produce a specific mix of calcium compounds, ammonium nitrate and phosphoric acid.

Some built-in facility in the plant exits for recycle and reuse of this carbon in the process itself, but due to unforeseen accidental failure of the system, some carbon slurry may be discharged for a short period. No liquid effluents are produced in this process.In the partial oxidation process finely divided carbon is produced. Catalytic steam reformation process is mostly adopted when naphtha is used as feedstock. The ash slurry from the direct scrubber recirculating water settling system containing some cyanides is also discharged to the ash pond.When naphtha is used as feed stock, the effluents from the oil gasification section and carbon recycle section contain high concentration of oil, in addition to the carbon particles and sulphide impurities.

0 kommentar(er)

0 kommentar(er)